Technology & Innovation

Strengthen the awareness of high-quality development and promote the process of branding.

Since its establishment, the company has always adhered to green and environment-friendly production, selected high-end cooperative suppliers, constantly introduced new technologies and materials, and driven the innovative production of packaging materials with the concept of sustainable development to achieve a virtuous circle of the industry.

To accelerate the green and low-carbon scientific and technological revolution, Haofei Industry not only pays attention to the research and development of green and low-carbon technologies, but also strives to make a full chain layout from basic research, breakthrough in key core technologies to comprehensive demonstration, seize opportunities, meet challenges, and achieve self-reliance in high-level science and technology.

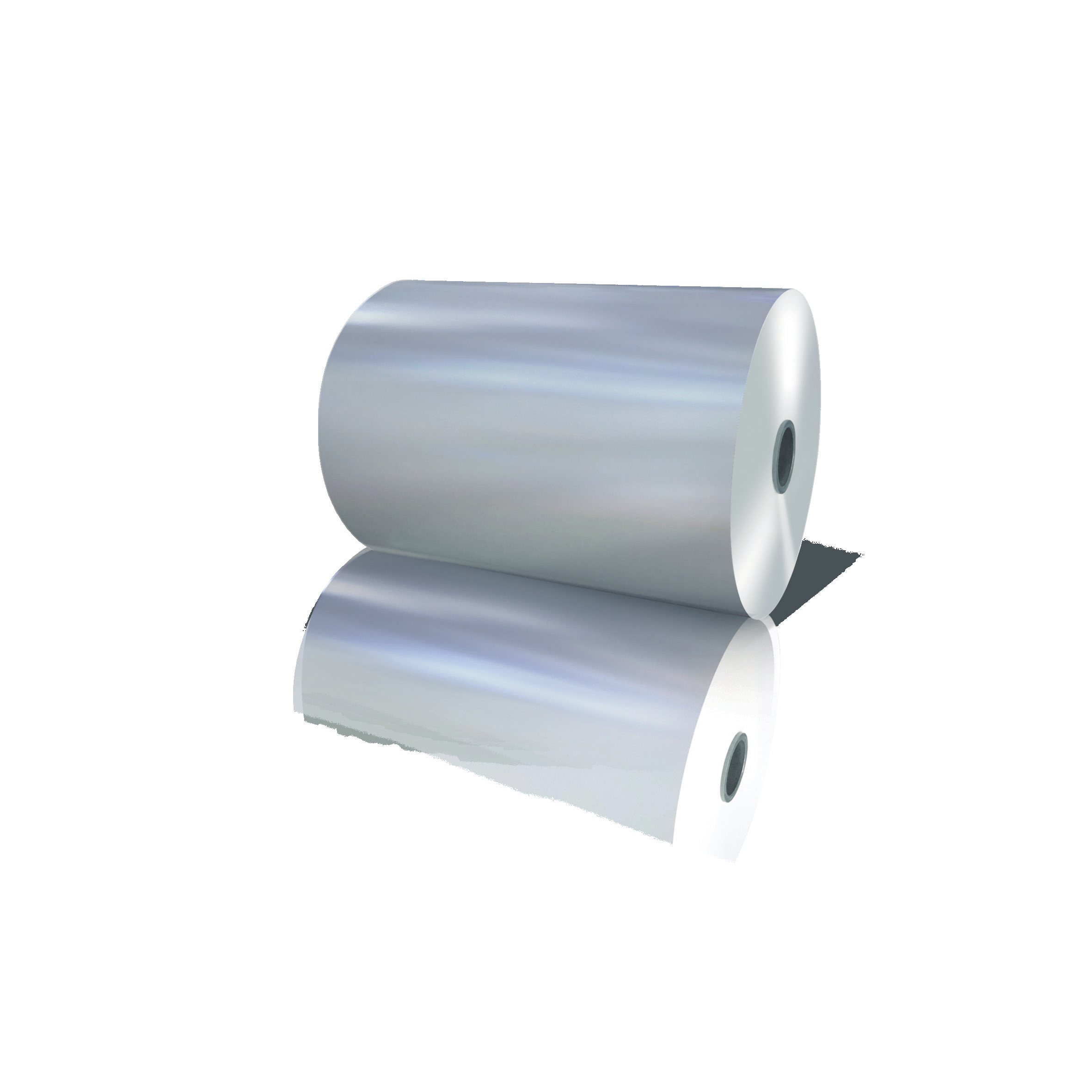

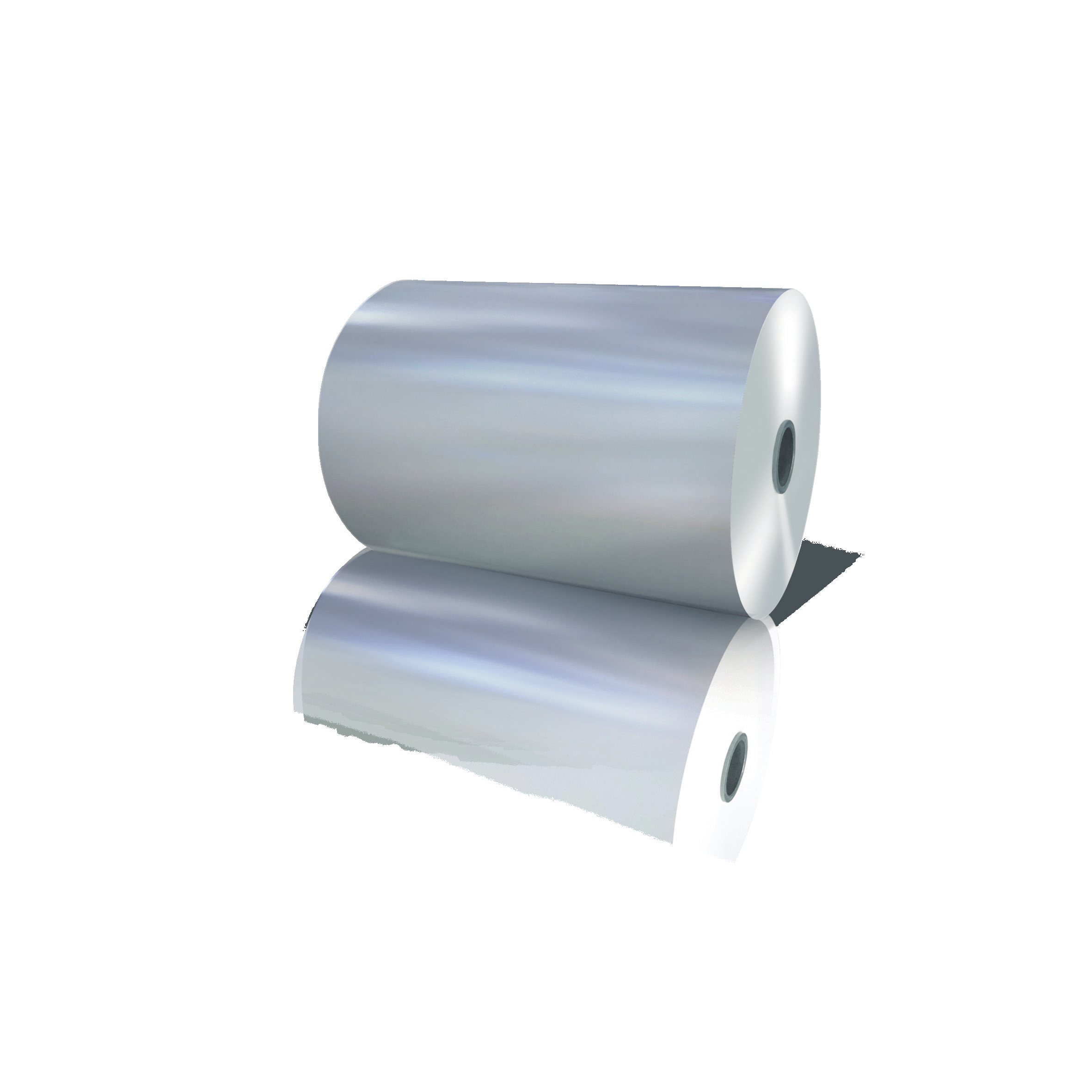

BOPP flat film

BOPP matting film

BOPP heat sealing film

BOPP pearlescent film

PETG film

R&D Center

Haofei Testing Room, based on different types of products in the production line, has three testing laboratories. According to product requirements, testing equipment is constantly improved and added. Relying on national inspection standards, world-class instruments and equipment, detailed job responsibility division, strict safety operation procedures, comprehensive product testing, and improved emergency response plans, it gathers technical talents, builds a collaborative team to tackle key problems, and forms scientific and technological innovation strength.

Haofei Testing Room is responsible for the incoming inspection of raw and auxiliary materials, production process control and inspection of finished products; Formulate and revise the quality standards and inspection operation procedures of the inspected products; Evaluate the quality stability of products; Formulate management methods for equipment, instruments, reagents, standard samples, etc. for inspection; Formulate and implement the company's standard innovation work plan, and cooperate with the production department to tackle technical problems.

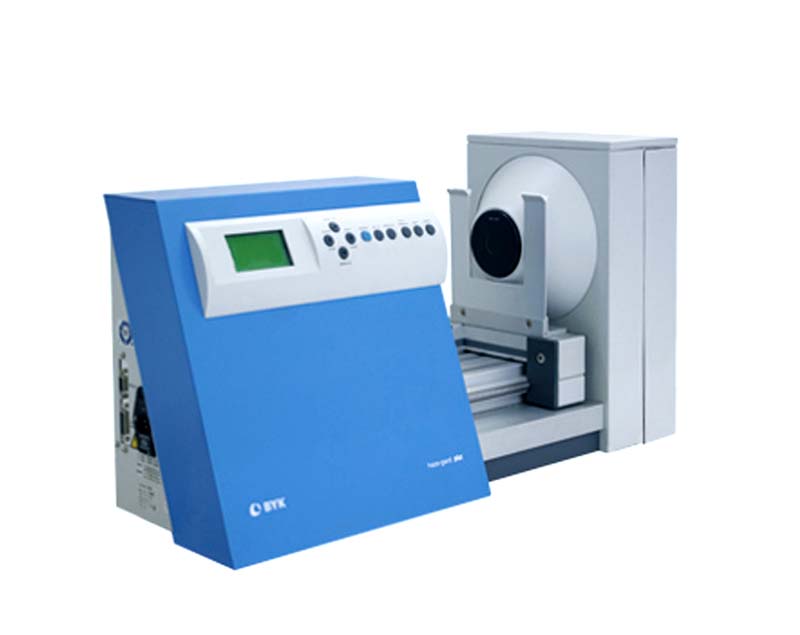

The main testing equipment in the three testing rooms are German Mal thickness gauge, German Brugger heat sealing instrument, BYK haze meter, electronic universal material testing machine, FRANK melt index meter, Mettler electronic analytical balance, glossmeter, color difference meter, friction coefficient meter, paper tube compression tester, etc. With advanced testing instruments and skilled analysts, the reliability and accuracy of the test results are ensured, and the work efficiency is greatly improved.

Relying on the powerful equipment, technology and personnel strength of the side examination room, Haofei Industry will continue to optimize the product structure, strengthen the construction of the talent team, promote self-reliance in science and technology, seize every moment to break through the "choke" problem, encourage innovation and guidance, provide efficient services, and strive to master the key core technologies in our own hands, so as to build Haofei Industry with ingenuity.

-

Electronic balance

High measuring accuracy, measuring accuracy 0.0001g

-

Electronic universal material testing machine

High measurement accuracy, force measurement accuracy indication ± 0.5%

-

Friction coefficient tester

High measurement accuracy: ± 0.02mN/m

-

Inductive thickness gauge

High measurement accuracy, accuracy ± ≤ 0.1 μ m

-

Haze/light transmittance meter

High measuring accuracy, measuring accuracy 0.01%

-

Heat sealing instrument

High measurement accuracy and high temperature stability. Measurement accuracy ± 0.2 ℃