Production Line

BOPP Film Introduction

- High mechanical strength

- Good stability

- Light and non-toxic

- moisture-proof

- Good sealing performance

- Good printability

Widely used in the market, it is honored as the "packaging queen" by the packaging industry

It is used in food, candy, cigarette, cold drink, juice, milk, adhesive tape substrate, woven bag composite and other packaging fields

Biaxially oriented polypropylene film is a flexible packaging material developed in the 1960s

The main raw materials are polypropylene mixed with additives with special functions, which are made into sheets through the die head of the extruder, and then stretched in two directions (longitudinal and transverse) at a certain temperature and at a set speed in a special stretcher, which are cooled appropriately and corona treated

-

About 50 times

Total tensile ratio

-

10-60 μm

Thickness range

-

100-550 m/min

Production speed

International advanced five layer co extrusion new multi-functional biaxially oriented polypropylene film production line

Haofei Industry introduced the 8.2 m high-speed production line in Bruckner, Germany, and the ANDRITZ production line in Austria to produce 10-60 μ M Printing film, composite film, matting film, pearlescent film of different specifications, as well as functional BOPP films such as atomized release film, building material film, synthetic paper, pearl film imitation paper film, high-strength adhesive tape film, with an annual production capacity of 72000 tons

PETG Film Introduction

- Good viscosity

- Good toughness

- High transparency

- Rapid forming

- Chemical resistance

- Strong resistance to stress whitening

PETG material is the abbreviation of heat shrinkable polyester film. It is a transparent plastic (amorphous copolyester), which can be quickly hot formed or extruded and blown.

PETG is a new environmental protection material, which is made of the same material as the bottle and degrades at the same time. It is widely used in the outer packaging of heterosexual beverage bottles and cosmetics.

PETG products will be more widely used in the high-end market

With the increase of population and consumption level, the market demand will increase day by day. After the new PETG project, not only new production capacity has been increased, but also new plastic varieties have been developed, laying a solid foundation for Haofei to become the largest plastic industry base in the north.

Our new PETG project is equipped with one set of slitting machine for two stretching lines:

-

17000 ton

Planned annual output

-

4.8 M

Film width

Shandong Yongjian engineering equipment is used for the main line, and Hangzhou Dahua equipment is used for cutting and slitting, which will be officially put into production in June 2022

The company is currently vigorously promoting the construction progress of PETG film project:

4 PETG production lines are planned

Estimated production capacity: 35000 tons

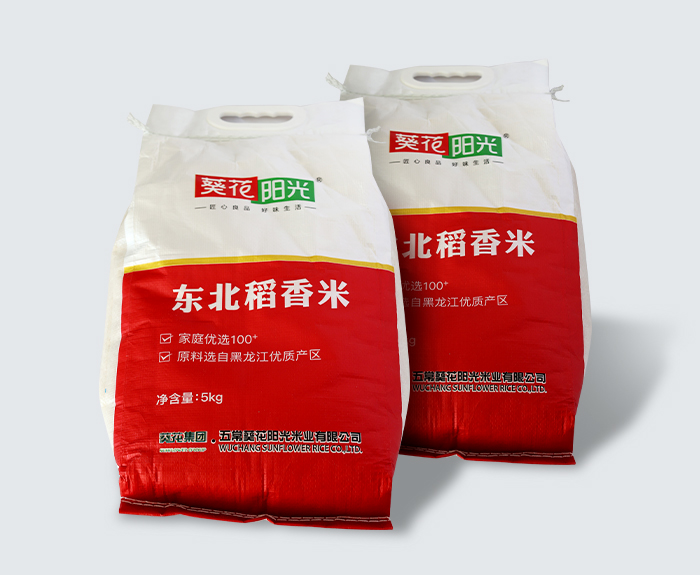

Product Application

BOPP Film

BOPP Film With the advantages of high mechanical strength, good stability, light weight, non-toxic, moisture-proof, good sealing, wide market application, good printability, etc., it is widely used in food, candy, cigarettes, cold drinks, juice, milk, adhesive tape substrate, woven bag composite and other packaging fields.

PETG Film

PETG Film The product is highly transparent and has excellent impact resistance, which is particularly suitable for forming thick wall transparent products. Its processing and molding performance is excellent. It can be designed in any shape according to the designer's intention, and is widely used in food packaging, cosmetics packaging, medical packaging and other fields.